Tradition and innovation:

According to oral tradition, iron was smelted in the local area long before the foundry was established. Therefore, foundry is not only a tradition of the local population, but also a kind of heritage passed down in families from generation to generation.

1854

Ferdynand Sattler arrives in the area of today's Drawski Młyn. He takes over the existing steelworks and names it "Odlewnia Żelaza i Fabryka Maszyn" ( Iron Foundry and Machine Factory ), which is called "Sattler's Steelworks" for short. This is how the story of the Foundry in Drawski Młyn begins.

1893 – 1914

The foundry is owned by subsequent owners. During this time, the production increases and the range of manufactured equipment is expanding, which included all the necessary equipment for a farm. Only grey cast iron was used for production.

1914 - 1918

During World War I, the Foundry continued to function, but attempts were made to change its production profile to meet the needs of war. In 1916, the first attempts were made to produce white malleable cast iron.

1920 - 1930

The first years of the post-war period were a time of failure and difficult financial situation both in the country and in the Foundry. The new owners come to the rescue: Eng. Ludwik Kembliński and attorney Kazimierz Czapski.

Since then, the company has been called "Drawska Lejarnia Żelaza i Fabryka Maszyn L. Kembliński i S-ka." Their control causes that the situation of the Foundry improves significantly. The owners focus on highly qualified employees and the expansion of the plant.

1936 – 1939

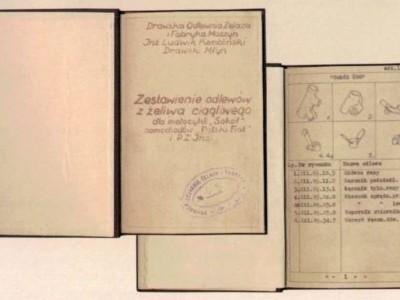

The production of black malleable cast iron was launched - a new type of cast iron not produced in Poland so far.

In the inter-war period, complex castings for the automotive industry were already produced - for "Polski Fiat" cars and "Sokół" motorcycles.

1939 – 1945

The times of World War II were another difficult period in the history of the Foundry. Firstly, the factory was closed for a few months, then some of the machines were taken to the Reich. The company's staff had to face difficult working conditions, and the production profile was intended to meet the needs of German companies.

1946 - 1989

Industry nationalization occurs. The company gets a new name - "Odlewnia Żeliwa Ciągliwego in Drawski Młyn, State-owned Separated Company" and remains a state-owned factory until the end of 1995. Over the next years, the plant is rebuilt and modernized.

1989

As a result of structural changes in the Polish economy, production collapsed rapidly. The market conditions in Poland forced restructuring measures - the implementation of new types of cast iron (at the beginning grey cast iron, and in the following years ductile iron) and opening to new markets, including exports.

→ Explore our product diversity today

1996

Transformation of the state-owned company "Odlewnia Żeliwa Ciągliwego" into the joint stock company "Odlewnia Żeliwa DRAWSKI S.A.", in which the majority stake is owned by private persons.

2002

- launching of the Disamatic 2013 MK1 Line

2006

- launching of the Disamatic 2013 MK5 Line

- purchase of the SPECTRO MAXX spectrometer

- purchase of the STEM cleaning machines

2007

- core nest

- Laempe L10 and L15 shooters

2011

- launching of the DISA MATCH 28''/32'' line

2019

- purchase of MagmaSoft software

- purchase of a core dryer

2020

- commissioning of a new melting department

- purchase of Laempe L10 and L20 shooters